As robots enter our lives, worrying incidents continue to come to the agenda. In a recent incident, an engineer at a Tesla factory was attacked by a robot. This incident has once again brought attention to Tesla, which is known for its history of work safety.

In this incident at Tesla’s Giga factory near Austin, Texas, an engineer was attacked by an engineered robot while troubleshooting. The robot’s task was to pick up and move freshly cast aluminum car parts. However, at the time of the incident, the engineer was programming software for two other Tesla robots nearby that had been shut down. Two other employees who witnessed the incident observed that the engineer was injured by the robot’s attack, “leaving an open wound on his hand”.

Such incidents illustrate the risks associated with the use of automation and robotics in industrial settings. Tesla’s track record on workplace safety puts this incident in a broader context. The measures the company will take to prevent such situations and better protect its employees are eagerly awaited.

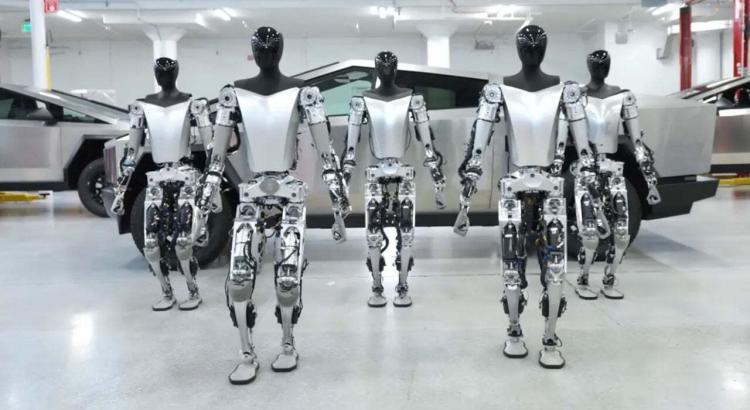

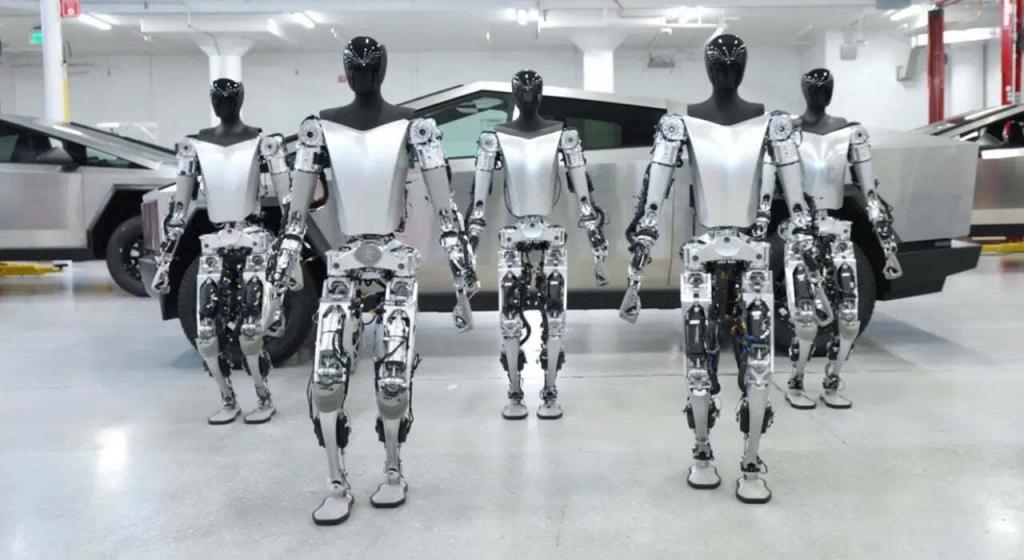

Tesla and Robot Workers

The incident came to light in a 2021 accident report submitted to Tavis County and federal regulators. While 2021 or 2022 did not see another autonomous robot accident at Tesla’s Texas factory, it comes at a time of growing concern about the use of autonomous robots in the workplace.

Increasing reports of injuries due to violence perpetrated by robot workers in Amazon’s fulfillment centers, killer droid surgeons, self-driving cars, and even robotic chess instructors have some people questioning the rapid integration of new technologies. The injury report that Tesla had to submit in order to maintain its lucrative tax breaks in Texas claimed that the engineer did not need to take time off work.

Tesla

However, an attorney representing contract workers at Tesla’s Giga Texas factory told DailyMail.com that he believes the number of injuries that occurred at the factory was underreported.

In fact, the injuries and death of one employee who lost his life were not included in mandatory reports. Other news outlets have also reported that Tesla sent employees required training materials in PDF files without sufficient time and that training was not provided in a reasonable manner. These cases demonstrate the need for Tesla to adopt a more effective approach to occupational safety and training.

Are Robots Revolting?

According to information shared with The Information by two witnesses in the most recent accident, the incident appears to have been more serious than Tesla reported. According to reports, the engineer suffered a deep cut and an open wound on his left hand, but was required to take a “zero day” leave to get away from work. Eyewitnesses say the incident occurred at Tesla’s Texas factory, where chassis are assembled, and the engineer was only able to escape the robot’s clutches when another employee pressed the emergency stop button.

Once free, the engineer fell several meters down a chute designed to collect scrap aluminum, leaving a bloody trail, The Information reports. This exposes weaknesses in Tesla’s safety protocols and shortcomings in how it responds to accidents.

As The Information highlights, Tesla’s self-reported injury figures suggest that by 2022, nearly one in every 21 employees will have been involved in an accident. This represents a high rate compared to the US industry standard of 30, and highlights the need for the company to make improvements to its workplace safety measures. This incident once again highlights the need for Tesla to review its safety standards and take measures to protect its employees more effectively.